Multislide Stamping Components

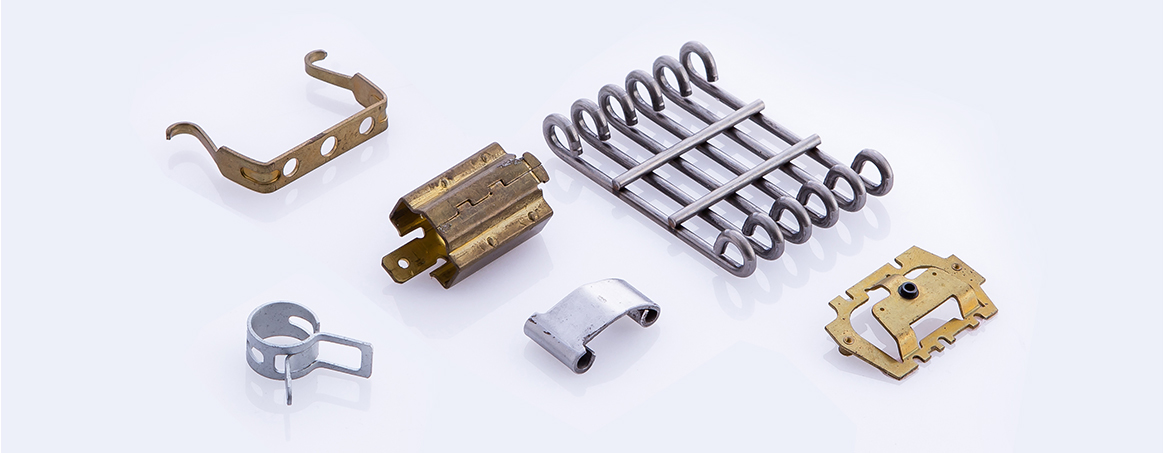

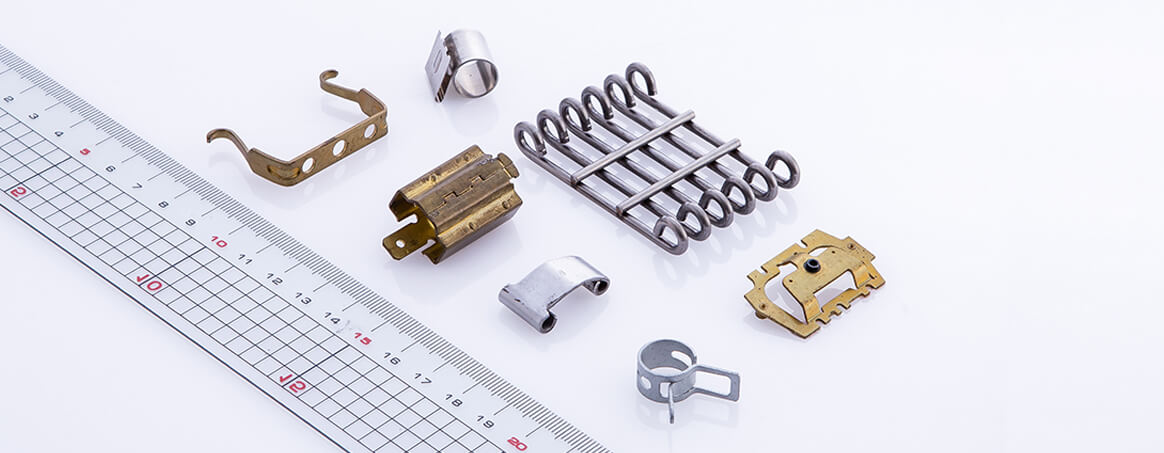

Products showcase:

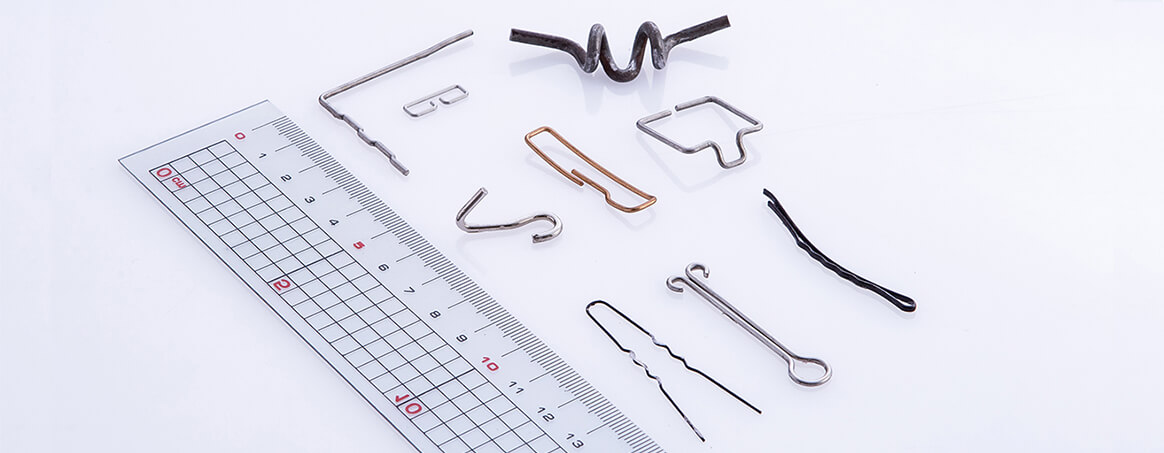

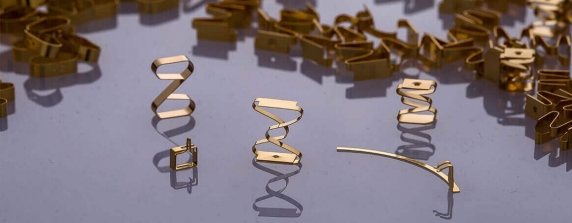

EMI spring contacts (also known as spring fingers, EMI contact fingers, SMD EMI fingers, antenna contacts, grounding springs, shielding fingers), electrical contacts, connector, antenna, switch hardware, automobile components, metal clips, hose clamps, 3D wire forms, high precision metal stamping components, fourslide stamping components, etc.

Multislide Stamping Components

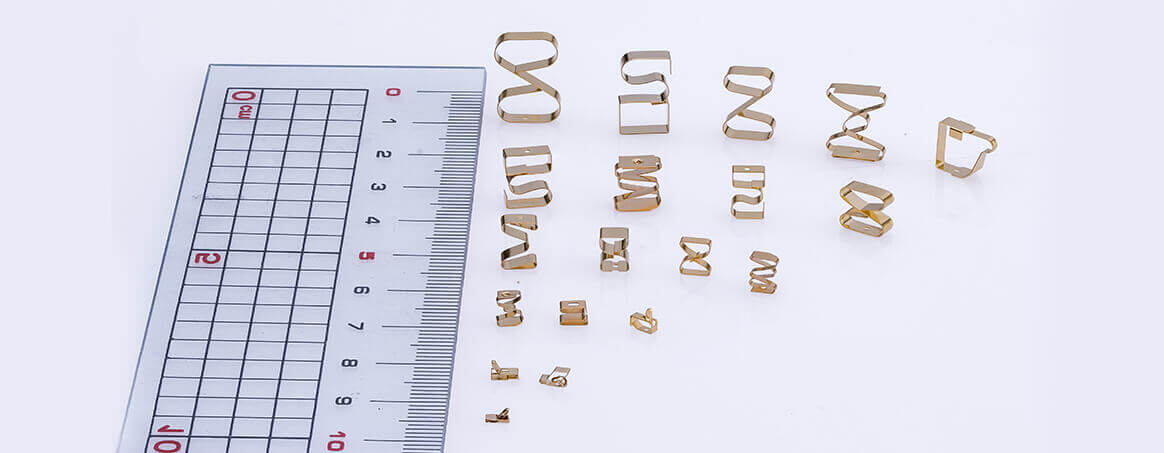

Most metal sheet components can be manufactured with stamping press, which allows speedy mass production. The development of die set, however, could cost more. If expensive metal sheet is used for manufacture, the scrap metal punched away after stamping could cause additional waste of raw material cost. Furthermore, highly complex shapes and bends cannot be completed due to the limitation of up-down stroke in a vertical motion. In order to overcome these challenges, we apply multislide stamping machinery that combines straightener, stamping press unit and sliding tools including shafts, cams and slides. By using the material of the same width as the desired workpiece, the operation allows the feeds to be leveled by the straightener and then transferred to the stamping press and later be bended and shaped by forming tools. The forming tools are installed on several slides driven by cams on shafts that move continuously to complete production. Integrating stamping and forming operations, this versatile application solves the problems of single-motion stamping press and works ideally for 3D components and high precision miniature products made of expensive raw material. This operation applies to wire forming as well except that it does not require the stamping process.

We develop stamping and forming tools based on customers’ specifications in the manufacture of high precision wire forming and metal stamping components. With CCD monitoring device, we also guarantee high yield rate and top quality.

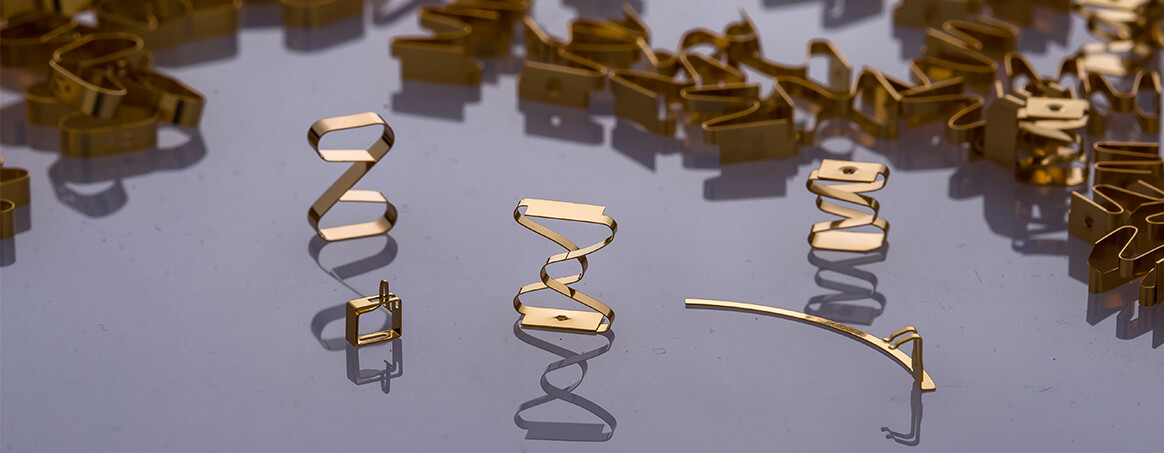

As leading automobile components and hose clamps manufacturers worldwide. We specialize in the development and manufacture of micro and miniature precision sheet metal forming parts. EMI spring finger contacts, for example, are micro components of various shapes and measurements. Spring finger contacts, also known as shield fingers, grounding EMI or RFI contacts, springs or clips, can be widely used in all industrial categories. Since electronic devices generate electromagnetic waves that might cause malfunction and could harm human health, spring finger contacts serve as a convenient and efficient way to block adverse electromagnetic waves. Spring finger contacts can be made of different materials, but beryllium copper is by far the best choice. Because of its material characteristics, it can achieve the following purposes more effectively:

1. Electrical conductivity

2. Eliminate electromagnetic waves (EMI)

3. High flexibility used for earthing or grounding

4. High temperature resistance

5. Solderability

Spring finger contacts are most commonly used in the following products:

1. Circuit boards for all industries.

2. Connectors for computer accessories such as USB, printers, screens, microphones, headphones, etc. When the computer is connected to

these accessories, some components might generate noises to interfere with these external communication accessories. ESD static

electricity may also destroy these electronic components or affect sensitive analog audio electronics.

3. Internal transfer points: Connectors for external modules such as battery contacts, floppy disk connectors, CD or DVD, etc., may cause

electromagnetic interference due to changes in impedance matching.

As modern electronic appliances design trend to be slim and miniaturized, electromagnetic interference generated by product circuits become an inevitable problem in the design process. How to efficiently reduce the electromagnetic interference with product performance has become the biggest challenge for engineers.

Spring finger contacts and EMI shielding reduce the time required for product development and inspection. They have become the most cost-efficient choice for manufacturers in order to comply with EMC standards.