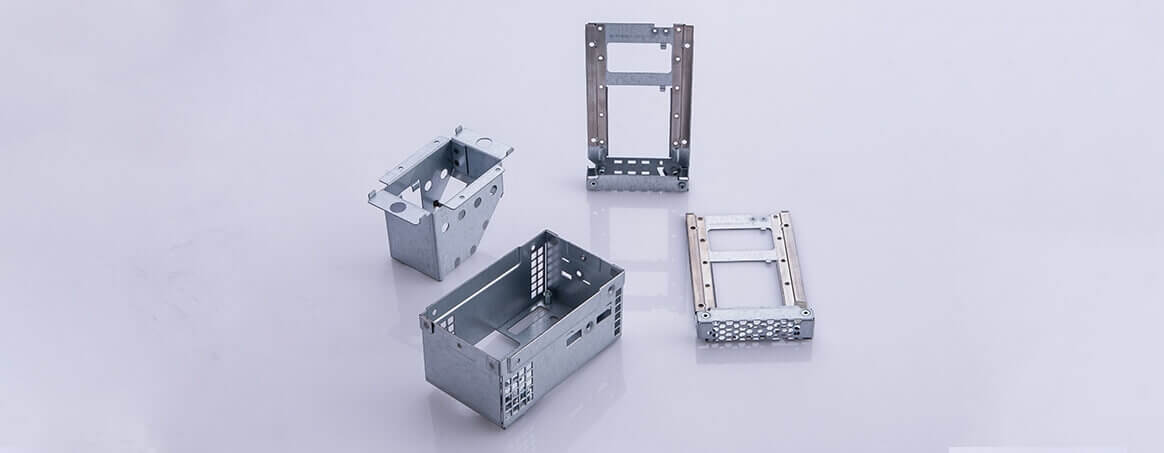

Custom Metal Stamping

Custom Metal Stamping

This type of sheet stamping requires the custom die set to be installed inside the press for the whole roll of material or the pre-tailored feed of material to be transferred to a fixed position in the lower die set. The upper die set then continues with the up-down motions successively to perform blanking, punching, perforating, bending or forming to finish the stamping parts based on product specifications and desired shapes, be it flat of three-dimensional.

Key points to manufacturing top-quality stamping parts are as follows:

1. Material selection: In the first phase of stamping parts design process, the die design engineers take into account the shapes and materials of the neighboring parts in their applications and the environment where the finished product will be used. Different requirements for malleability or functionality, environmental temperature, humidity, corrosion resistance, durability, etc. will all affect the choice of materials. Die set development costs and time can both be largely reduced with thorough evaluation in advance.

2. Stamping press selection: The decision whether to use single stage dies or progressive dies for production depends on the thickness, width and shape complexity of the stamping parts along with the annual market demand. The manufacturing capacity, however, differs with the tonnage of the stamping press.

3. Die design expertise: After the stamping press and the production method have been decided, die design ability is critical to the success of your products. Our engineers with decades of experience in tool and die design have tackled countless tough challenges in high-complexity precision stamping die set designs. After carefully evaluating drawings and blueprints provided by our customers, our experts always conduct thorough communications with customers and apply computer simulations for design analysis, modification and optimization before proceeding to die set production. Our goal is to ensure completion of tool and die design economically and efficiently and to satisfy any high-precision manufacturing requirements.

We view customers’ success as our top priority and treat production of each stamping part with utmost dedication. In light of current heated global competition, we provide cost-efficient assembly services to include welding, boding, screwing, riveting and other metal works for a complete start-to-finish production process. Whether our customers are seeking packaged solutions or an order for single parts, or requiring special surface treatment or special packaging services, we will work with you every step of the way to guarantee the highest level of satisfaction.