Custom Springs

Products showcase:

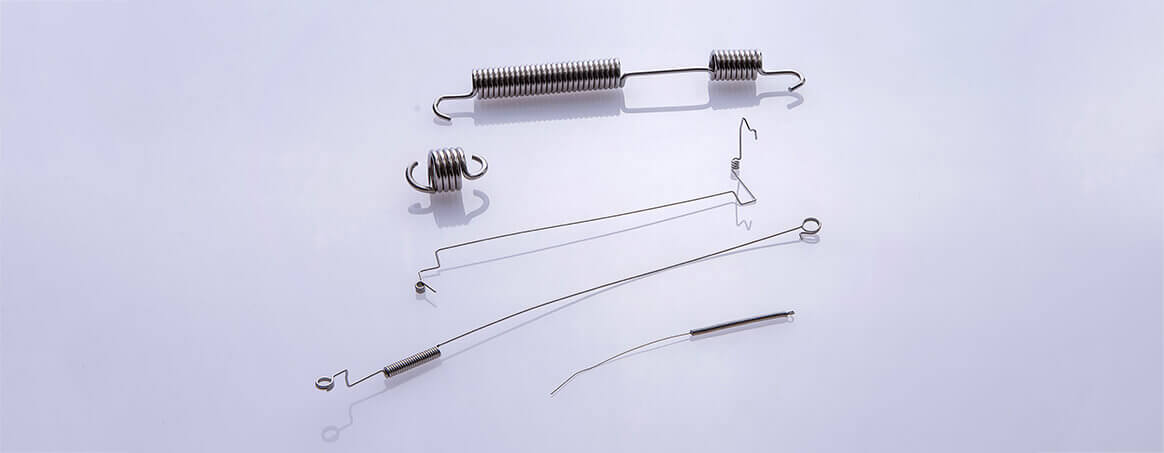

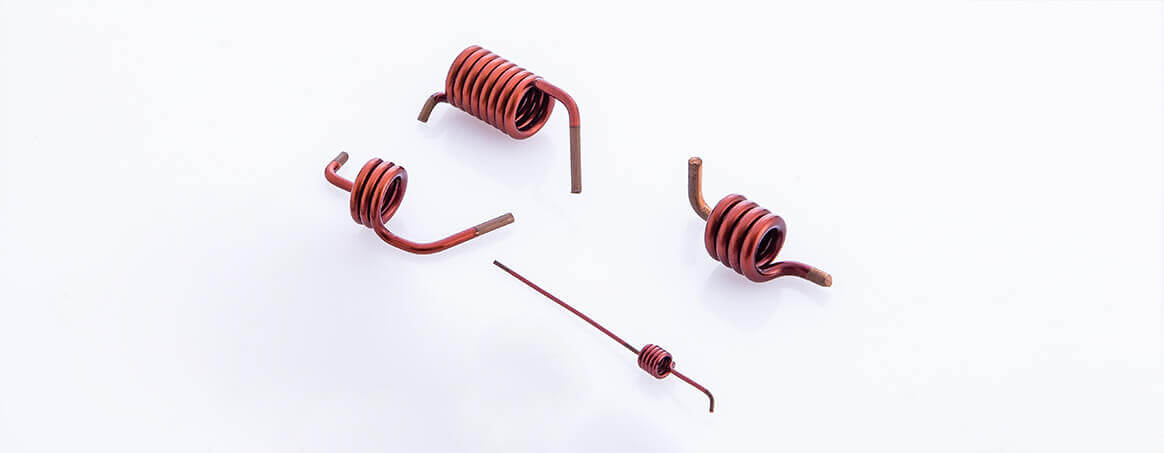

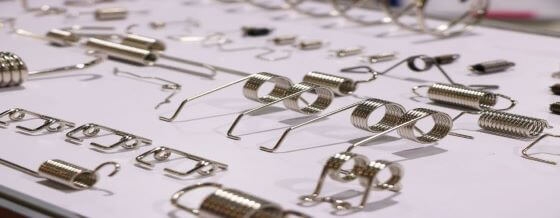

Extension springs, precise torsion springs, torsion springs, double-torsion springs, constant force springs, wave springs, air coils, wire forms, etc.Custom Springs

Springs, made of metal wires, are processed with two different methods: hot winding and cold coiling. Hot winding and cold coiling have their respective advantages and disadvantages, which cannot be generalized.

Hot winding is widely used to manufacture springs of larger wire diameters in mass production, mainly for the train and automobile industries. Cold coiling, on the contrary, is used to make more diverse types of springs of smaller wire sizes in smaller quantities. Each method requires different process and equipment, with its own treatment and technology involved.

There are not many manufacturers in production of the hot wound spring due to its limited applications. Therefore, we focus on the discussions of more commonly used cold coiled springs. The majority of torsion springs manufacturers adopt cold coiling technology because of its light weight and flexibility. To meet greater market demands for various types of springs of small quantities, future development of cold coiling technology will be on the rise.

After years of development, springs have been put into mass production for industrial purposes. Therefore, a number of springs have been standardized by manufacturers such as die springs, disc springs, etc. However, there are more springs yet to be designed to cater to our needs. Some springs are visible in our daily life. But more are hidden in many objects, yet to be discovered only through disassembling. Designed to meet any required specifications of the end products, springs come in a wide range of shapes to serve various functional purposes including reducing shocks from any motion, permitting freedom of movement between components, maintaining electrical continuity, counterbalancing a weight or thrust, storing energy and engaging contact between components, etc.

A spring can be made into various shapes from straightening and shaping wires by forming machines. There are a large number of spring designs, broken down into five primary categories:

- Extension springs

- Torsion springs

- Compression springs

- Wire forms

- Constant force springs

We use the most compatible CNC spring machines in the spring production to match customers’ specifications and requirements. Our specialties include the making of precision extension springs (width: 0.1-1.0mm), double-torsion springs and wire forms (width: 0.2-5.0mm).

Besides the aforementioned most common types of springs, we also manufacture custom springs including constant force springs, precise torsion springs, spiral springs, wave springs, air coils, etc. Other special coil shapes, for example, including oval, rectangular or flat springs, can also be manufactured by adjusting tooling designs on our machines.

The requirements for springs made in various shapes and specifications pose challenges for custom torsion springs manufacturers. In order to meet the diverse demands of the spring market, our technicians strive to advance up-to-date spring setup technology with the goal to provide state-of-the-art products and also offer custom spring design services.

With accumulated experience for years, our main business lines include not only springs but also sheet metal forming stamping parts, multislide stamping components, lathe parts, screws, etc. Our products are made of a wide range of materials and have been used in various applications. We take strong pride in our strength in customized design and manufacturing. Please do not hesitate to contact us if you have complicated product designs and configurations with high precision requirements.

Besides our experienced technicians that possess exceptional skills, we have procured many advanced multi-axes camless spring machines to improve our manufacturing technology and capacity. The addition of these new machines help boost our production capacity in the manufacture of various types of precision and intricate springs. Please refer to the video of our latest models as follows: